Gulf Rubber Capabilities

As part of the Skellerup Group, we draw on over 100 years of experience with high quality rubber and plastic products, and work with customers from product conception to delivery.

Through innovative thinking, custom enhanced designs, global manufacturing and distribution, excellent service, and certified quality, we give our customers the competitive edge. All you need is one company. That’s why we are your single trusted source.

Our Process and Services

Consultation

Understanding your product as a whole, the parts, the processes of assembly, and most importantly – your pain points – help our engineering team design a better custom solution for your bottom line.

Material Science and Development

Gulf’s experts in engineering, physics, and chemistry design and develop new materials to create better products and streamline your complex production process.

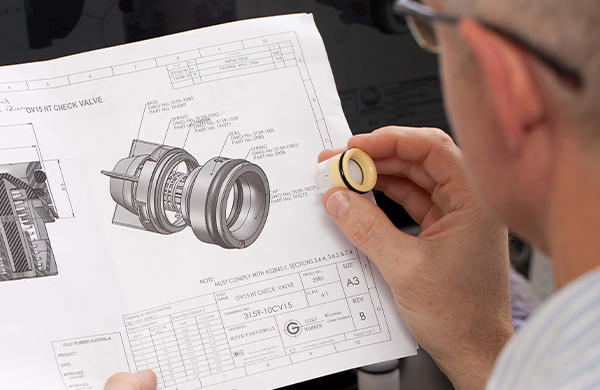

Engineering and Design

Gulf has over 40 years manufacturing precision engineered rubber and plastics. Our engineers and cutting edge technology create tailored material solutions delivering the performance you require.

Compounding and Mixing

With a focus on research and development, we are experts in blending raw materials and developing compounds with specific properties to suit your custom application.

Rapid Prototyping

Our engineering solutions team can cost-effectively concept, test, and validate multi-element component designs within hours or days as part of our unique rapid prototyping process.

Molding and Overmolding

Our factories combine precision engineered rubber and polymers into a single product, and in many cases we help clients with overmolding components to reduce additional steps, quality assurance, and time to market.

Assembly and Sub-Assembly

If we are pre-combining components before integrating into assembly, or combining two or more sub-assemblies, we'll streamline your production and simplify your supply chain.

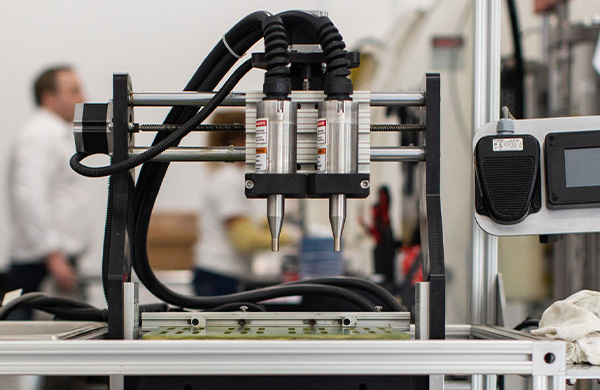

ISO Class 7 Cleanroom

Gulf's ISO Class 7 cleanroom houses research and development activities utilizing state-of-the-art equipment demonstrating our commitment to innovation and manufacturing the highest quality, precision engineered medical device components and assemblies in the industry.

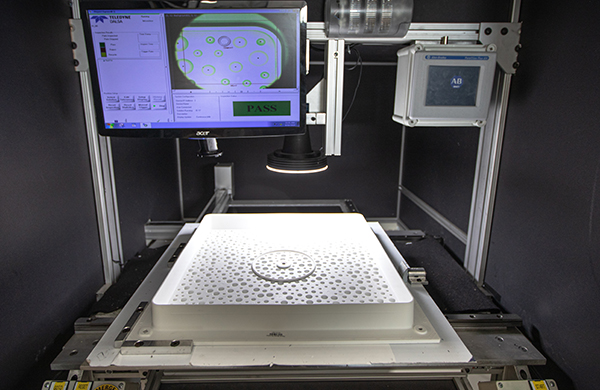

Functional and Performance Testing

Our quality engineers run products through rigorous functional and performance testing including tensile and tear strength, stress relaxation, and compound rheology to ensure your product meets specifications.

In-House Quality Lab

Gulf has a fully equipped metrology lab, Micro Vu, and the ability to characterize rubber. The in-house quality lab holds both TS 16149 and ISO 9001 certificates, and we employ stringent process controls and use dependable tools.

Packaging Solutions

Our packaging meets the demand for high standards and our expert team is constantly innovating to improve weight, strength, thickness, cost efficiency, and sustainability.

Shipping and Logistics

The versatility of our truly global business means providing reliable supply, service, and support anywhere in the world meeting all specifications and delivery times.